Description

1. first of all ,the min-able material of mine,will be transferred to the production site of factory . in this system ,raw materials consist of : (shale ,soil ,clay ,fire clay ,plastic ,sand ,cement,…)

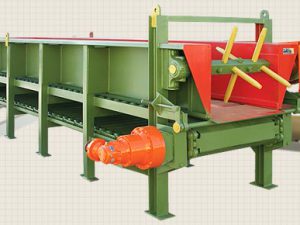

2. mineral material to be kept from of depot in the factory and stored based an the use of line production in early part of line production on box feeder. Work of box feeder is transport raw materials based on a production line and provide them.

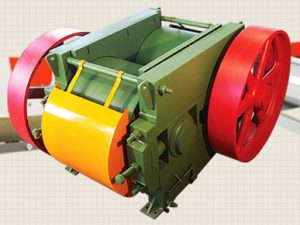

3. Raw material transfer from box feeder set to mills set by balance conveyor . the work of mills is grind the raw material with grain size of 0 to 20 mm. this set has steel blades and anti-wear plates that are cause of shatter raw material and preparation of soil.

4. If there is stone or root of plants in soil or raw material ,you can used of stone remover and shaker set . in stone remover set all of stone that cause creation nitrate in the final product will be removed from the soil .in shaker set all of root remove and grains of raw material will be adjustment ,this set prevent from exist of clutch in raw material by vibration and anti-wear steel grates. If you use to clay ;shale system doesn’t need to add moisture and it naturally used of moisture soil . this moisture is between 5% until 3% that there is soil naturally .

Of course,if you use of else materials and need to add moisture in this step , it add to raw material by mixer set

5. in this part raw material transport to large 50 tons tank by conveyor that each tank will be filled based on product demand. That these tanks are causing homogenization of moisture in raw materials and produce beneficial bacteria to fermentation the raw material . this system is cause to create improvement quality of final product especially brick , further more it cause to create computational brick and optimization the power consumption. If you would like ,up to 10 different product mix with each other in this line that it depends on the final product.

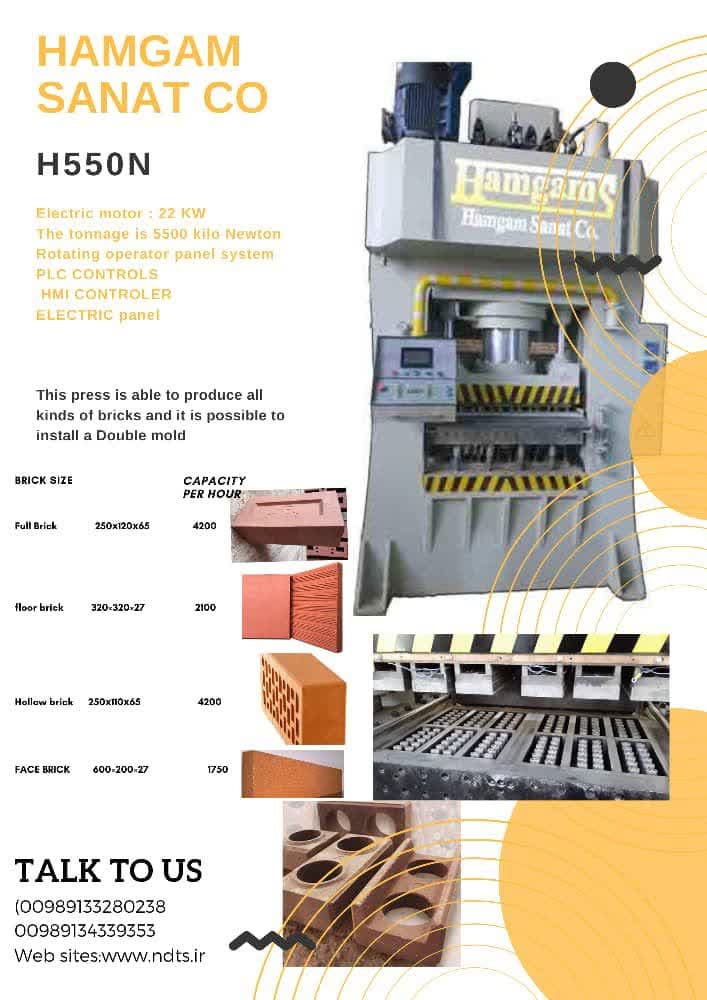

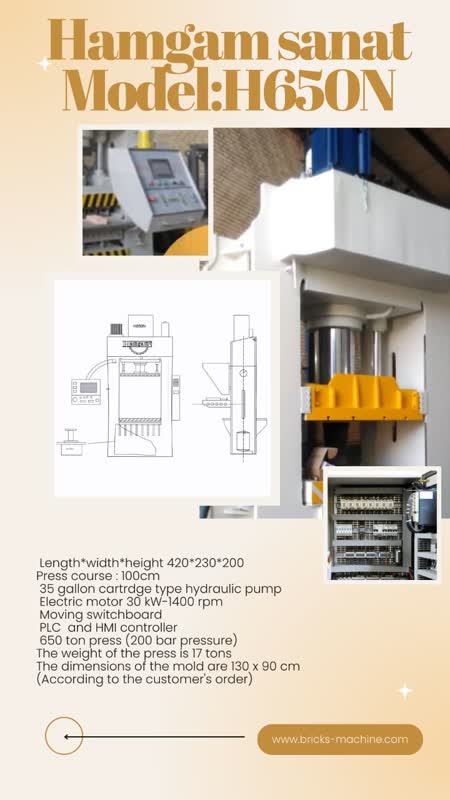

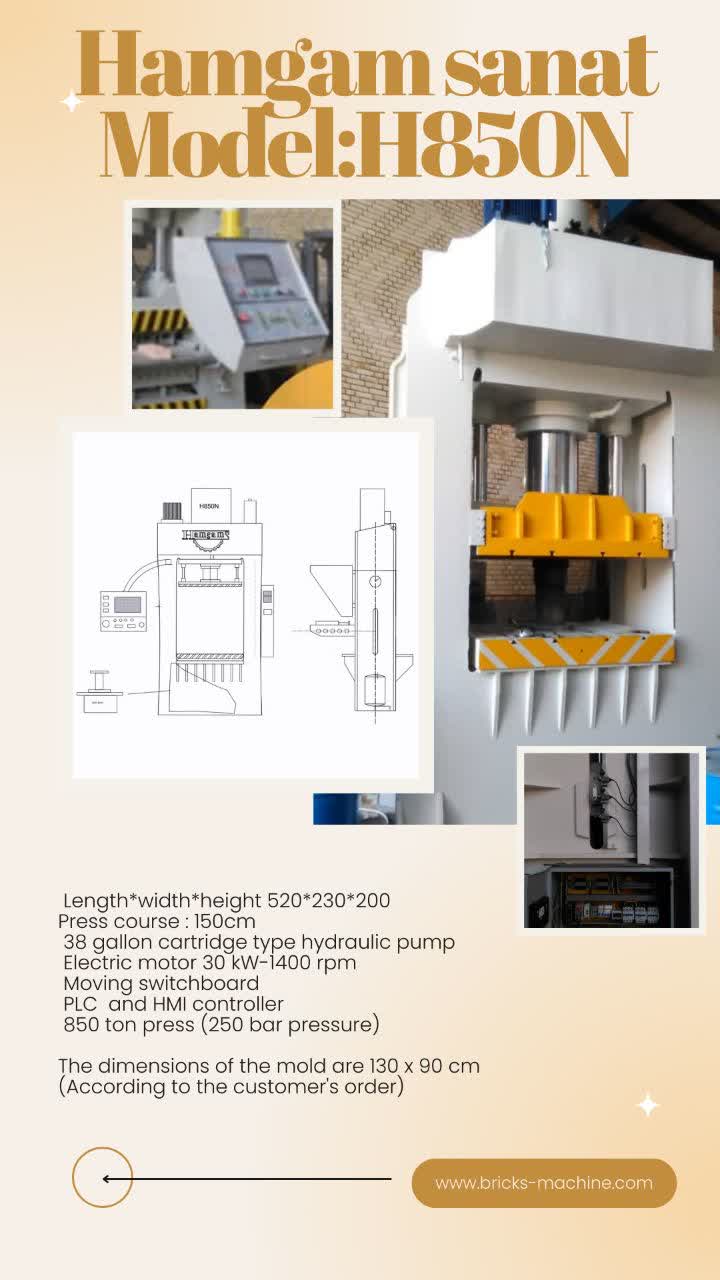

6.in this part , raw material transport to the 10 tons tank automatically then they transport to the dry hydraulic press by feeder in this stage , each press operator can select that want which raw material combine with each other and product by his. Her press. All of these step are automatically , height of the soil in these tanks are automatically and done in tell gently .

7. in this step raw material will be injected automatically capacity of each press is based on the kind of production and raw material and other bricks product brick is between 1500 and 7000 bricks per hour.

In this system, only one person as operator is enough for each press and doesn’t need to add moisture after the bricks will be transferred to the nearly furnace by lift truck machine or wagon .After production in the automatic system raw brick will transported to the furnace by special rails. There is the possibility of using a tunnel or Roller or shuttle furnace that Homgam Sanat Sepahan company do making and consultation of all these furnace

8 all the advice about production and the shape and size of the produced bricks after freely to customer in this company ..

9. the advantage of this system can be noted that in this system there is no move the bricks to drier and its reason is law humidity of raw material and this is one of the reasons of low cost and economical of this system than extrude production line 28% water and same system

Reviews

There are no reviews yet.