Description

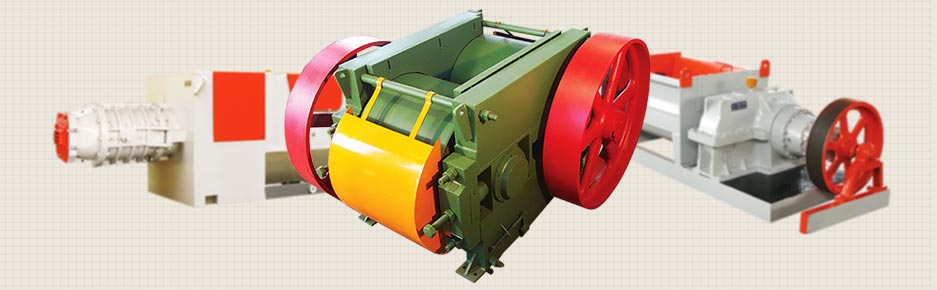

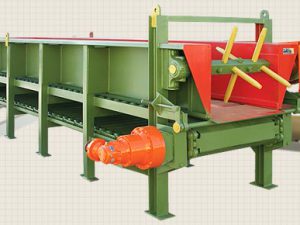

This machine is used for making mud in clay brick production lines.

Main body: made of ST 37 steel sheet and GS 45 casting parts by welding and stress relief

Shafts: made of DIN-1.1191 steel

Waltz roller: alloy cast iron with cream and nickel in casting, turning and stone work

Anchor light: cast iron

Bearings: cast iron

Bearings: from reputable brands

Mud cleaning system: they work mechanically (it can be equipped with a pneumatic system if the customer orders)

Safety system: mechanical fuse (if the customer orders, installing a safety system equipped with hydraulic BACK UP jacks reinforced by nitrogen gas)

Reviews

There are no reviews yet.